Our Partnership With Macgregor

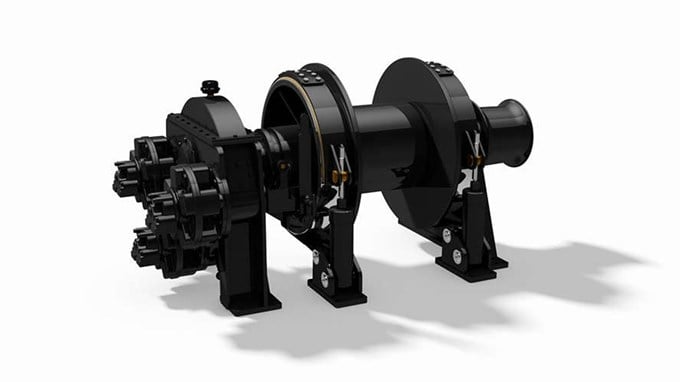

Harbour assist hawser winches

MacGregor’s range of hawser winches is an ideal choice for harbour assist tugboats and for a wide variety of mooring applications. They are robust and reliable and offer proven heavy-duty performance.

A MacGregor hawser winch features:

- A brake force of up to 200 tonnes

- Custom drum sizes to fit hawser capacity requirements

- Built-in redundancy with multiple motor gearboxes

- Electric and hydraulic drive unit options

General Purpose Crane - Cylinder (CCL)

MacGregor general purpose (GP) cranes are robust and solid, with components chosen for their durability even in the most hostile marine environment. They offer efficient, low-maintenance, all-purpose lifting capabilities.

MacGregor crane designs are based on our lengthy experience and are backed-up by unrivalled global service support and a proven track record of more than 13,000 crane deliveries worldwide over the past 50 years.

Electro-hydraulic GP cranes are self-contained units. The product range includes hydraulic cranes for service operations, stores handling and special applications, meeting every requirement under any condition.

The crane offers multiple benefits

- Robust and reliable design

- Self-contained

- Precise stepless speed control

- Easy to maintain

- Closed loop hydraulic system

- SWL 3t – 25t

All MacGregor hydraulic cranes are built upon the latest closed loop hydraulic design.

Power swivel with Active Rotation Control (ARC)

Positioning cargo in port is a difficult and time-consuming job for the crane driver. Limited vision, heavy rain and wind make it even more complicated. A load can start rotating in the air and stopping this motion requires a highly-skilled crane driver. Even for an experienced driver, this operation takes a lot of time and effort.

MacGregor has developed an active rotation control (ARC) system for its range of MacGregor cranes that stabilises and automatically rotates a load in the air; making load-handling faster, reducing cargo damage and saving energy.

The ARC system has an automatic swivel control that maintains the cargo’s position during the entire operation. When activated, cargo positioning times can be shortened by up to 30 percent. Shorter positioning times and a smooth drive significantly lower energy consumption and increase efficiency. These ensure that the ARC solution pays for itself in a short period of time.

All MacGregor crane designs are based on our lengthy experience and backed-up by unrivalled global service support and a proven track record of more than 13,000 crane deliveries worldwide over the past 50 years.

Easy to use

It only takes a few minutes to learn how to use the system. There is a separate control box with two controls: one to set the start position and one to set the end position. With joystick control, the cargo’s position can be accurately fine-tuned

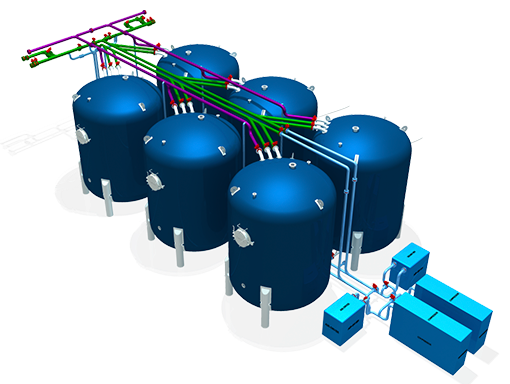

Dry bulk handling systems for offshore supply vessels

MacGregor bulk handling systems for offshore supply vessels enable the efficient transfer and storage of dry bulk cargo.

MacGregor offers two main system types: one uses a hopper and blow pump concept and the other employs a traditional pressurised tank storage and discharge system.

Technical solutions based on the MacGregor hopper and blow pump concept have been successfully employed on cement carriers for the past 20 years and are now available for installation on board AHTSs and PSVs.

It offers a great number of advantages for shipowners, shipbuilders and ship operators worldwide such as:

- A 50 to 70% increase in bulk capacity

- Space efficiency

- Low installation and maintenance costs

- Reduced risk of clogging

- Simplified piping

- Operator-friendly

- Environmentally-friendly

Electric cranes

MacGregor has delivered more than 600 electric cranes since 2007, with electric motor and drive system technology evolving significantly during this time. These developments have enabled the winch design, motor efficiency and cooling system to be further improved. As a result, the next generation electric crane is 15% more efficient than the first generation and up to 50% more efficient compared to the traditional closed-loop hydraulic design.

Electric drives are available for all merchant cranes in the MacGregor portfolio, including port, bulker, container, multi-purpose, and heavy lift cranes.

The crane offers multiple benefits to shipbuilders, owners and operators:

- Weight optimised by combination of NMF crane house design principles with MacGregor high tensile steel experience

- Improved reliability and safety by redundant power supply units and additional brakes

- Up to 50% lower energy consumption (especially during standby mode)

- Up to 50% lower fuel consumption

- Potential savings in capital expenditure through reduced generator size

- Smaller electric cables and no oil filling

- Superior cargo handling efficiency due to higher speeds and precision control, reducing time in port

- Increased operator & crew comfort through significantly reduced noise levels

- Lower maintenance costs without the need to change oil, oil filters, and hoses

- A sustainable choice that removes the risk of oil leakage

- Up to SWL (safe working load) 1,000T

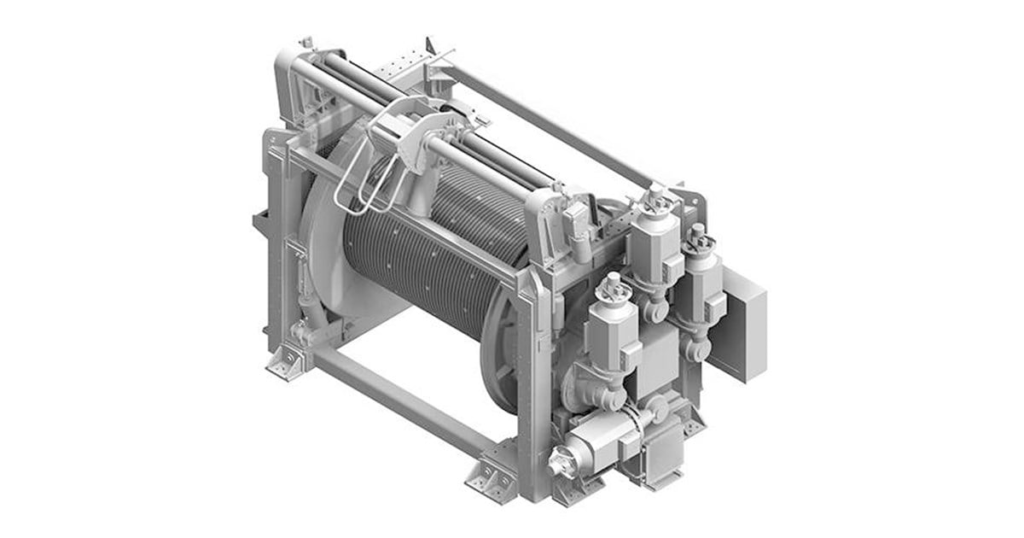

Electrical operated ROV winches

Available with electric or hydraulic drives, our MacGregor remotely operated vehicle (ROV) winches, with active heave compensation (AHC), can handle underwater ROV units even in the harshest conditions.

Electric-drive ROV winch features:

- Frequency-activated speed control

- Built-in redundancy with multiple patented MacGregor electric motors

- Lower energy consumption compared with hydraulic drives

MacGregor external lashing system

Unlike internal lashings, the external lashing system secures the lifting side of the container instead of the compressed side, which reduces both forces. This allows the container stacks to be loaded with a better weight distribution, with heavier containers higher up in the stacks, compared to an internal lashing system.

MacGregor’s external lashing system uses a variation of Flexilash equipment, with tailor-designed distances between knobs on the lashing bars to minimise the length of the turnbuckles and optimise handling when lashing different container heights. All external lashing systems are tailor-made to fit your vessel’s design.

FibreTrac crane

MacGregor’s dedicated fibre-rope offshore crane, FibreTrac, allows operators to use the full lifting capacity of the crane, at practically any depth, so a smaller crane and vessel can be used for more assignments, and owners are able to bid on a wider range of contracts.

This is made possible because of neutrally-buoyant, high-performance fibre rope. Fibre-rope weighs virtually nothing in water, so regardless of the length of rope used, it does not add anything to the load experienced by the crane. This is in complete contrast to steel wire cranes, which have to bear the load as well as the ever-increasing weight of wire paid out.

Gentle rope handling and a controlled environment safeguard the integrity of the fibre rope, guaranteeing a long lifetime.

Standard Features

- Lifting capacity up to 200t* single line/270t* double fall

- AHC direct on winch

- In-house developed control system

- Main winch can be mounted on the crane or below deck

- Auxiliary winches with up to 25t SWL and 4,000m wire capacity

- Fully-equipped, spacious, air-conditioned, ergonomically-designed operator cabin

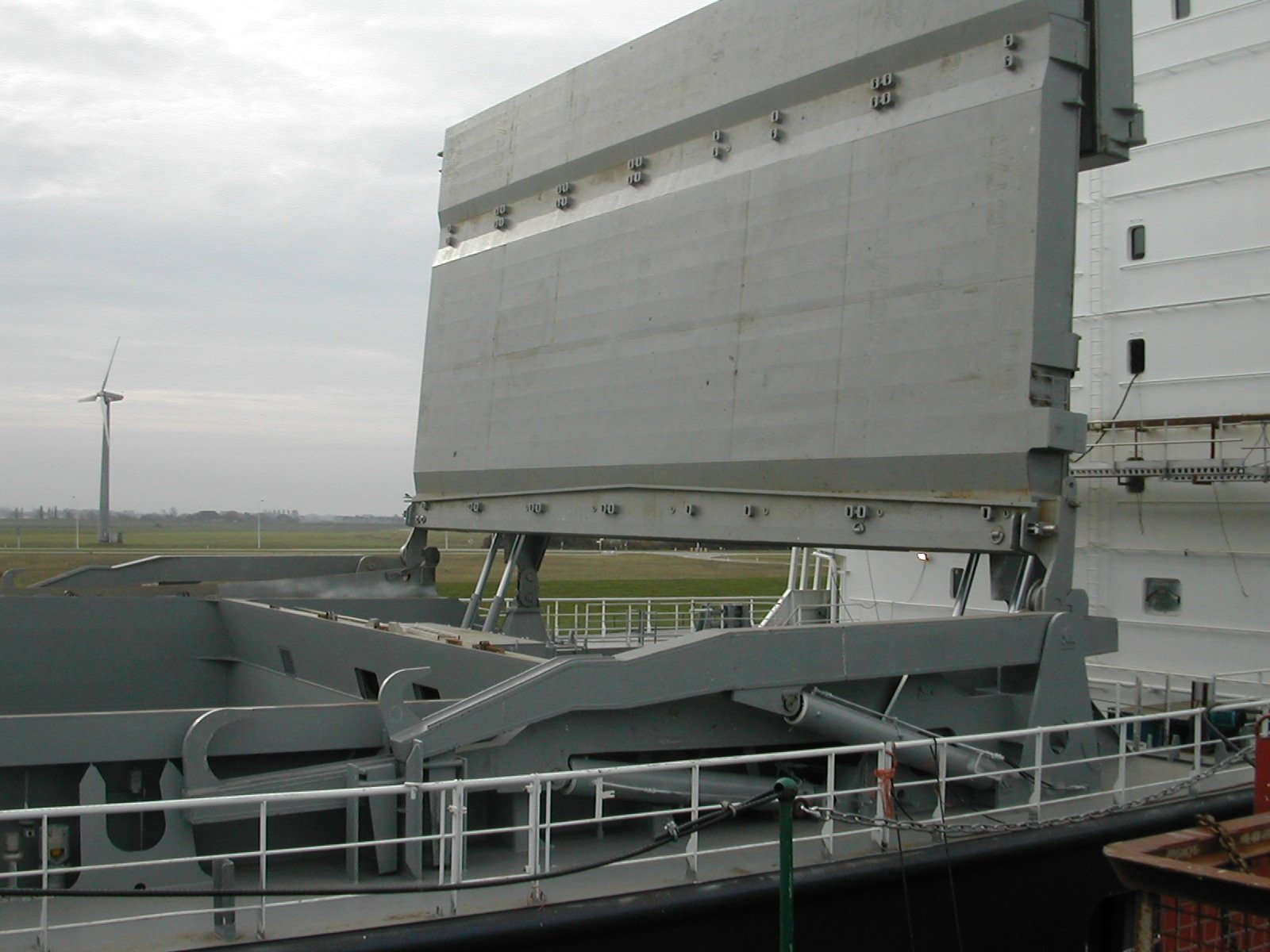

Folding hatch covers

It is important for all cargo ships that weather deck and cargo space layouts are designed with the highest possible level of cargo handling efficiency in mind. This allows for fast and safe loading. MacGregor makes sure that the arrangement of hatch covers, sealings, support pads and locators on board your ship are optimised to deliver uncompromised weathertightness to protect the cargo and to ensure safety.

The efficient use of cargo space is of utmost importance for general cargo vessels. Folding hatch covers are designed to carry various deck cargoes and to form functional cargo areas to facilitate flexible cargo operations. In an open position they provide access to the hold for loading and discharging cargo and in the closed position they seal the hatchway in a weathertight manner. Tweendeck folding hatch covers are also available.

MacGregor hydraulic folding covers consist of two (or more) panels, which are connected by hinges to form a folding pair. In many cases, the hatch cover comprises two folding pairs. One pair is stowed at the aft end of the hatch and the other forward.

The folding pair is operated by hydraulic cylinders acting directly on the end hinge arms, which are connected at stools on the deck. When the cylinders push the end panel up from the closed position, the cover folds and the second panel, fitted with wheels, rolls on rails to a stowage position. The panels are usually secured in the open position by semi-automatic locking devices interacting with the wheel arms.

FibreTrac crane

MacGregor G-type davits are specially designed for handling heavier fast rescue craft, workboats, daughter craft and personnel transfer boats.

Our philosophy is simple – safety and functionality go hand-in-hand. With more than 200 deliveries of G-type davits and well over a thousand davit deliveries in total, we have worked hard to really understand our customers’ needs.

Designed to operate with a safe working load of up to 22 tonnes, G-type davits are based on a hydraulically-operated frame with an automatic boat cradle, including a high-speed winch with a constant tension function, hydraulically-operated painter line boom, shock-absorber, anti-pendulum docking head and an integrated power pack. Other options are available on request.

- Type-approved by DNV GL

- High-speed winch system with speeds up to 60 m/min

- Constant tension system with speeds up to 120 m/min

- Integrated hydraulic power unit

- Supplied as one complete unit, ready for installation

JOCAM activities suit particularly the necessities of the Energy and allied sectors of the Nigerian economy.

Quick Links

Home

About Us

Our Services

Our Partners

Contact Us

Our Services

Engineering

Procurement

Support

Our Partners

Contact Us